2025-11-11

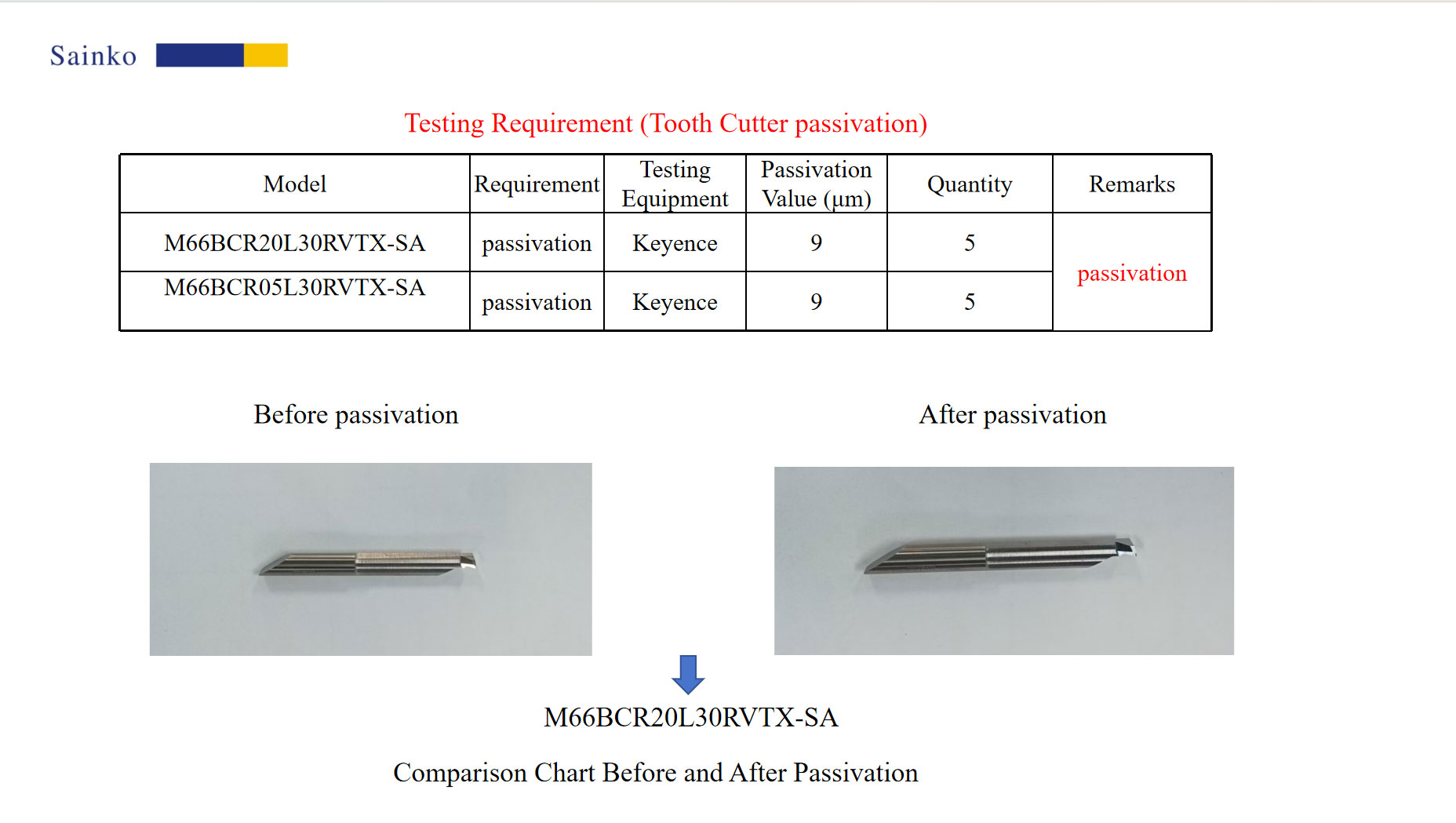

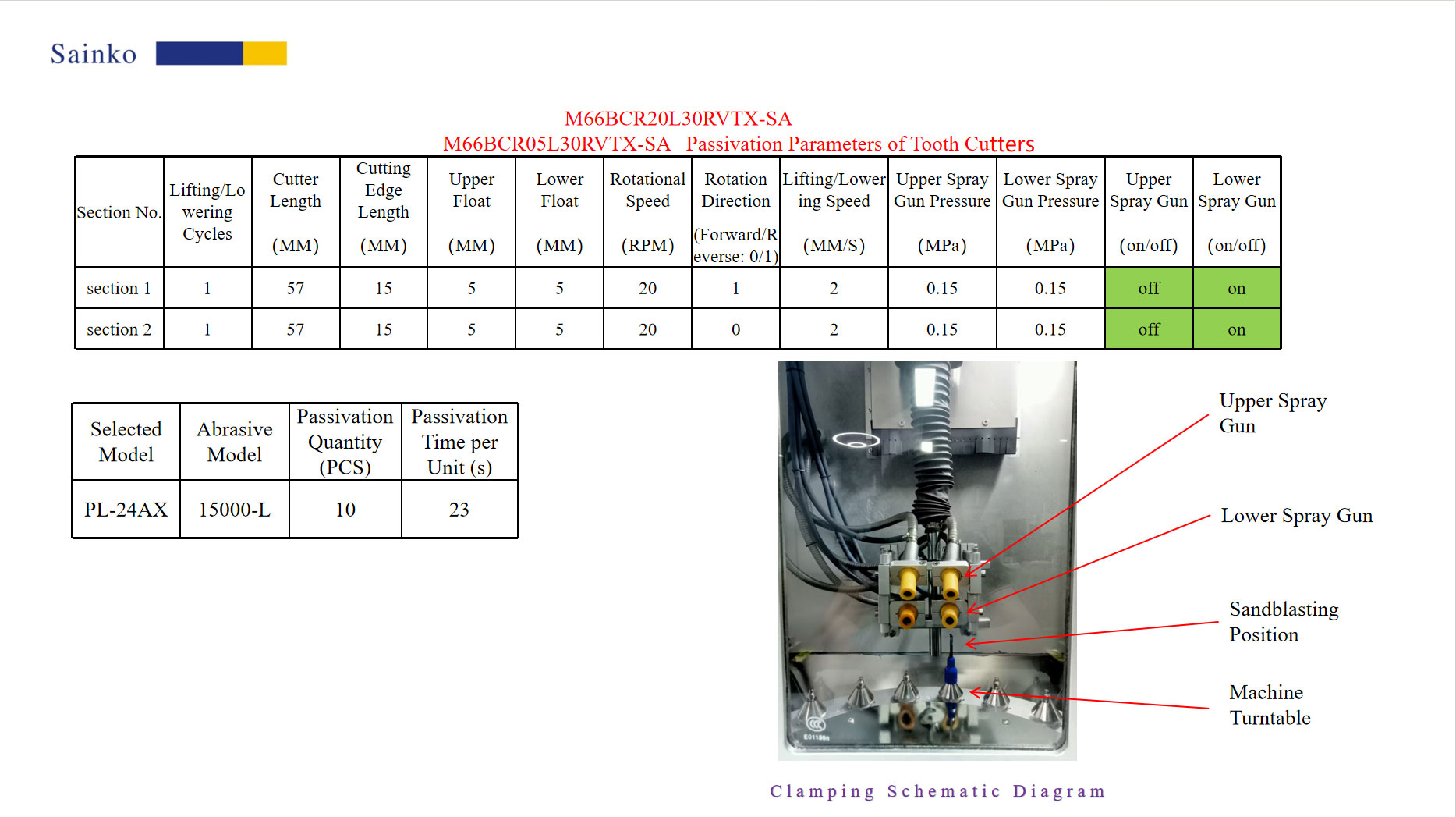

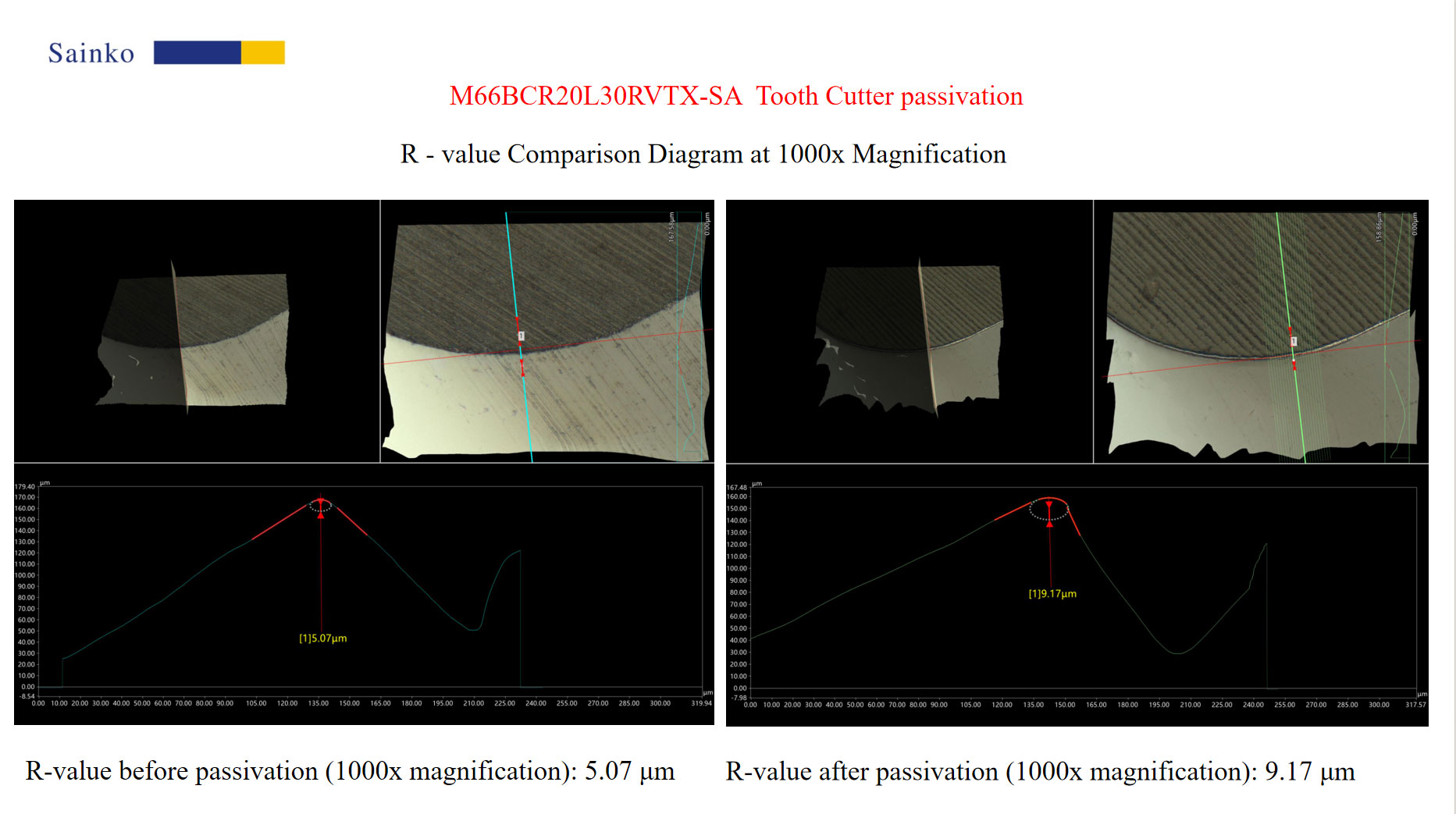

2025-11-11The test samples for this test are milling cutters provided by the customer, with models M66BCR20L30RVTX-SA/M66BCR05L30RVTX-SA, totaling 3 pieces. The core requirement is to passivate the milling cutter edge, and the passivation value needs to reach the standard of 7 μ m. To accurately meet the requirements, our company adopts PL-24AX passivation equipment and uses 15000-L abrasive for processing.

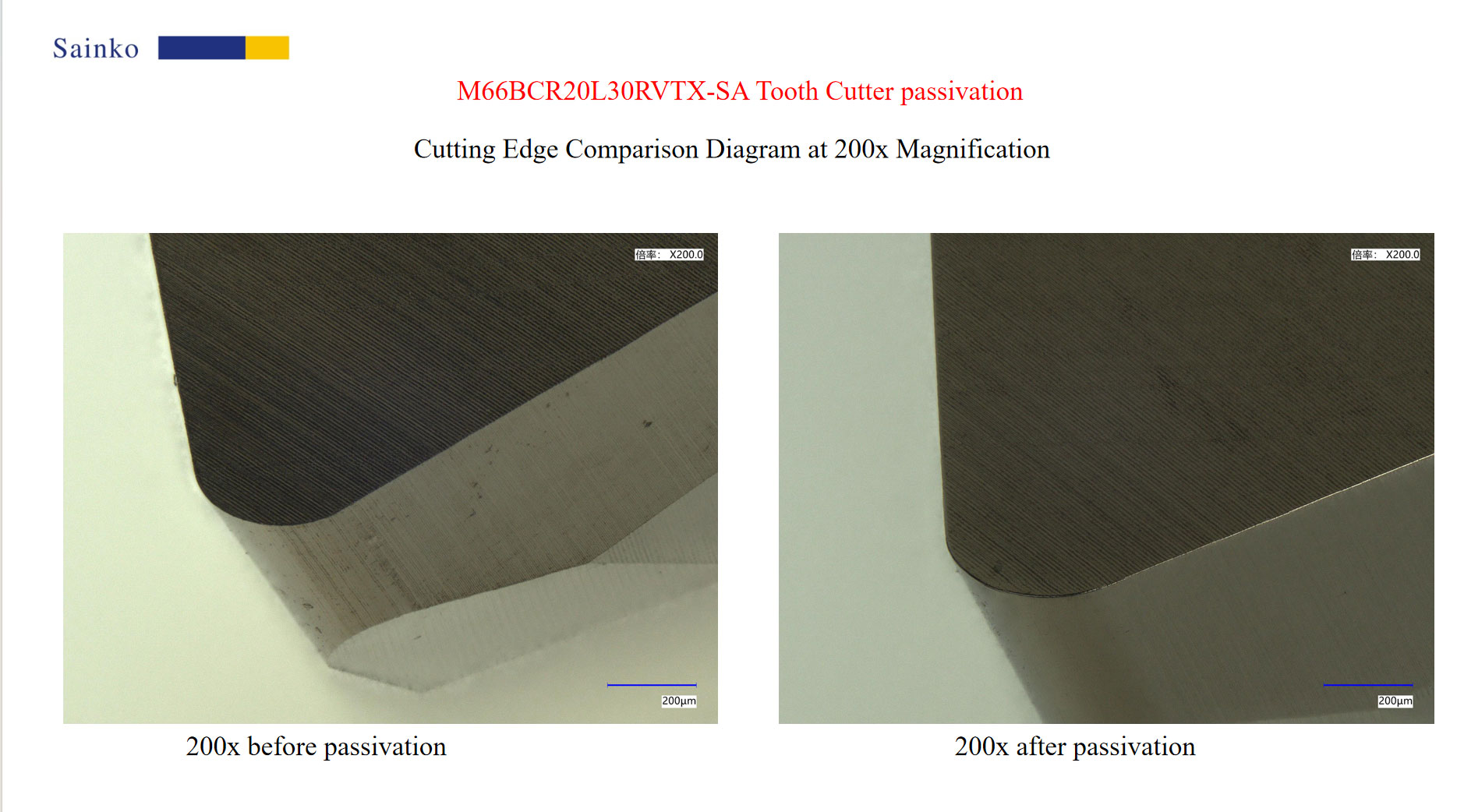

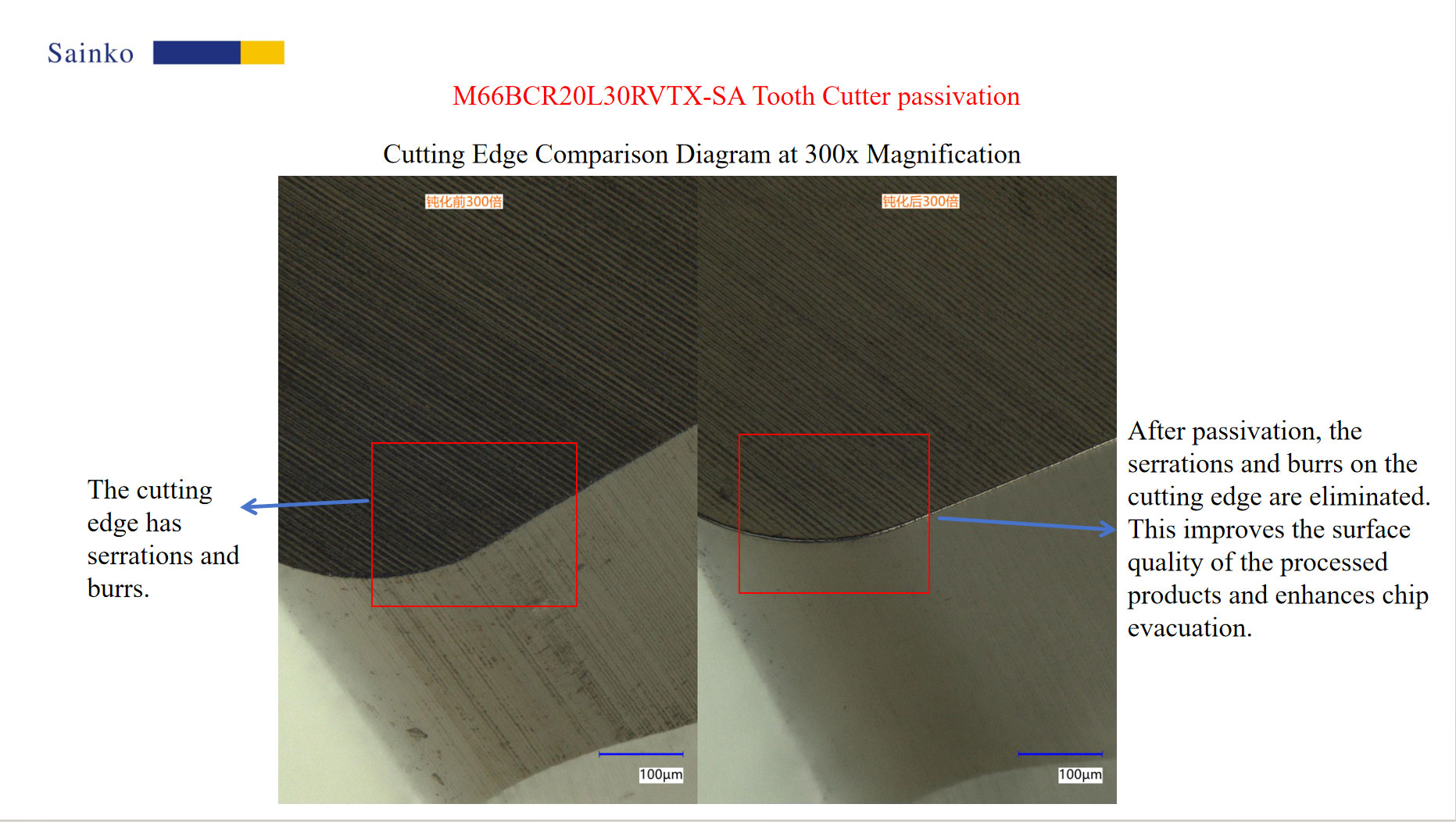

During the processing, precise control of parameters such as passivation speed (20 RPM), up and down float (5 mm), lifting speed (2 mm/s), and spray gun pressure (0.15 MPa) is achieved through equipment. The opening and closing states of the upper and lower spray guns are adjusted according to the two-stage process settings to achieve uniform grinding and fine polishing of the cutting edge. Combined with the fine grinding effect of abrasives, the passivation values of the three milling cutters finally stabilized at the preset standard of 7 μ m, while effectively eliminating the original serrations and burrs on the cutting edge.

After subsequent verification, the passivated milling cutter not only significantly improves the surface smoothness of the workpiece during cutting, but also optimizes the chip discharge effect, effectively reducing chip accumulation and workpiece scratches. The specific test results are detailed in this report.